Soldering Irons: what to consider when buying one

There are many soldering irons on the market- selecting the right one may not always be easy - read our buying guide to find out what to look for.

Home » Construction & manufacture » this page

Soldering Tutorial Includes:

Soldering basics

Manual soldering: how to solder

Soldering irons

Tools for soldering

Solder - what it is and how to use it

De-soldering - the secrets of how to do it properly

Solder joints

PCB solder resist

See also: SMT soldering techniques for PCB assembly

In order to be able to solder properly, it is necessary to have the correct tools for the job. Before starting out a soldering iron has to be bought. As there is a very wide range of irons that are available, the choice of the correct one is necessary if the best job is to be made of building any circuits and projects.

Types of soldering iron

There are many different types of soldering iron that are available. Very broadly they can be split into three main categories:

- Basic air cooled irons: The most basic type of soldering iron has no temperature control apart from the cooling effect of the air and any work that the iron may be used with. These soldering irons can be bought quite cheaply and are OK for many applications, although they do not have the temperature control of some of the more advanced types.

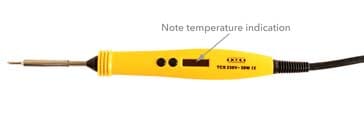

Basic soldering iron - Temperature controlled soldering iron: It is possible to place a thermostat within the soldering iron to provide temperature control of the bit. This enables the right temperature to be maintained at all times. A higher wattage element can be used for times when heat is being drawn from the bit without the temperature rising too high for good soldering.

Temperature controlled soldering iron with temperature indication

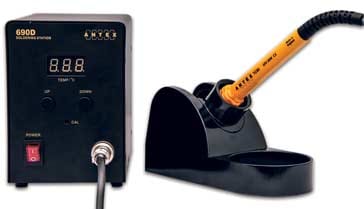

Temperature controlled irons normally have an adjustment to enable the required temperature to be set, and on some irons there may be an indication of the temperature. Temperature controlled soldering irons enable much better soldering to be achieved, although they are obviously more expensive than the very basic types. - Soldering iron workstation: Soldering iron workstations provide the optimum solution for a soldering iron.

Typical soldering iron workstation

Soldering iron specifications

There is a vast variety of soldering irons on the market, from the small to the large, and from the inexpensive to the very costly. Choosing the right one to meet your particular requirements is not always easy.

There are a number of features that the soldering irons possess that need to be examined before a choice of a particular soldering iron is made. These include: size, wattage or power consumption, voltage, method of temperature control, anti-static protection, type of stand available, and general maintenance and care issues.

- Size: There is a wide variety of sizes of soldering iron available. Obviously those that are smaller will be more suited to fine work, and those that are larger will be more suited to the solder of items that are less delicate. The physical size will also run in parallel with the wattage or power consumption of the iron.

- Wattage or power consumption: The power consumption or wattage of a soldering iron is often quoted. The wattage can vary. For basic non-temperature controlled irons, a wattage of 40 watts may be good for general work, and higher if heavy soldering is envisaged. For small PCB work, 15 or 25 watts is a good value. For temperature controlled irons slightly higher wattages are common as the temperature control acts more quickly if more heat can be directed to the bit more quickly to compensate for removal of heat via the work item.

- Voltage: While most soldering irons on sale in a particular will country will have the correct mains voltage, 230 V AC in the UK for example, 115 V AC for the USA, there are also soldering irons that can run from 12 V. Some irons may be made for specialist applications where they need to run from low voltages.

- Temperature control: Soldering irons use two main varieties of temperature control. The less expensive irons are regulated by the fact that when they come up to temperature, the loss of heat is the same as the heat generated. In other words they employ no form of electronic regulation. Other, more costly types have thermostatic control. This naturally regulates the temperature far better. Usually the temperature can be adjusted to the required value. These irons come into their own because when heat is drawn away by a large object being soldered, they will maintain their temperature far better. Those with no regulation may not be able to maintain their temperature sufficiently when soldering a large object, with the result that it is more difficult to melt the solder under these conditions.

- Anti-static protection: With the increasing susceptibility of many electronic components, particularly the very advanced integrated circuit chips, static protection is becoming more of an issue. While most components being used by home constructors are often not damaged by static, some are. It is therefore a wise precaution to at least consider whether the soldering iron that is bought is one that has static protection.

- Stand: The stand used for the soldering iron can be very important. With irns reaching temperatures of around 300C it is necessary to ensure they are well protected. A good stand is therefore essential.

- Maintenance: When using any soldering iron it is essential that spare parts can be obtained. The soldering iron "bits" used to undertake the actual soldering have a limited life and even though the rest of the iron may work for many years, it will be necessary to change the bits at regular intervals. Additionally it is worth ensuring for the more expensive soldering irons, such as those with temperature control, that spare parts are available should they need repair.

It is worth spending a little time looking at the pros and cons of the various soldering irons on the market. Some less expensive irons may be quite adequate for most jobs, but anyone considering a large amount of construction will reap the benefits of a more expensive temperature controlled soldering iron. It is a matter of choosing the right soldering iron for the work envisaged.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Construction Ideas & Concepts:

Soldering

SMT component soldering

ESD - Electro-Static Discharge

PCB manufacture

PCB assembly

Return to Constructional Techniques menu . . .