What is Soldering: techniques & technology

Understand the techniques and technology behind soldering so that you can make take the best options and make the best soldering for the situation.

Home » Construction & manufacture » this page

Soldering Tutorial Includes:

Soldering basics

Manual soldering: how to solder

Soldering irons

Tools for soldering

Solder - what it is and how to use it

De-soldering - the secrets of how to do it properly

Solder joints

PCB solder resist

See also: SMT soldering techniques for PCB assembly

Soldering is one of the key processes in the manufacture of electronic equipment. Soldering allows electronic components to be electrically and mechanically joined so that they provide good stable and reliable connections for the life of the product.

Accordingly soldering is at the heart of electronics construction and manufacture for the hobbyist and enthusiast or student as well as for small and large scale commercial organisations producing saleable electronic equipment of all forms on whatever scale is needed.

Whilst soldering is used in a variety of different industries including the plumbing trade where it is used to join pipes and seal them to prevent water leaking out, and it is used in the jewellery trade amongst others, it is key to the electronics industry.

The processes for solering, as well as the solder itself have be honed over many years to provide good quality reliable electrical joints as well as meeting the current health and safety and ecological requirements.

Origins of soldering

The concept of soldering has been know for very many years. Some silver solder joints have been found on items dating back to between 3000 and 2000 BC.

More recently soldering developed in the 19th Century for various craft uses and then with the advent of radio and later electronics around the beginning of the 20th Century it came into its own.

Initially a tin / lead solder was used, but as the health and general environmental issues of lead became of wider concern, lead-free soldering technology was introduced. In Europe RoHS directives required that electronic circuit boards were lead free by 1 July 2006. However even before this many countries and companies were turning to lead free soldering, often as a result of recycling pressures.

What is solder

It's no surprise that solder itself is at the very heart of soldering. It is the material that melts around a joint and solidifies to provide mechanical rigidity and electrical conductivity.

There are many different types of solder. Essentially solder can be defined as a fusible (i.e. it can melt and become solid again) metal alloy used to create a permanent bond between two or more metal items.

The solder is a metal alloy that has a much lower melting point than the main constituents, and in this way it can be made to melt at temperatures that can be attained relatively easily and without very specialised equipment.

Solder can be used in many areas, but the type of interest for making electrical connections must have a high degree of electrical conductivity. It also helps if it is resistant to corrosion, as this would mean the joints and their conductivity would degrade over time.

Soldering techniques

There are different techniques used for small scale and large scale soldering. Labour intensive schemes cannot be used for large scale manufacture, where high degrees of automation are needed to provide the throughput required, whereas small scale production for commercial enterprises as well as prototyping and home building and construction for hobbyists as well as students, etc require soldering techniques that do not require the large scale investment and set up needed for mass production.

Two of the major approaches to soldering include:

- Mass production soldering: Mass scale production uses soldering techniques including wave soldering and now more commonly techniques like infrared reflow where the components are mounted on a board and all the components are soldered at the same time.

- Small scale production: For small scale production and home construction manual soldering techniques with the use of a soldering iron and solder wire are the most widely used method. Some skill is required to make neat and effective joints, but this can be learned quite easily. This type of soldering technique can be used for making small projects, soldering PCBs, making leads and a host of other applications.

Read more about . . . . manual soldering.

Tools for soldering

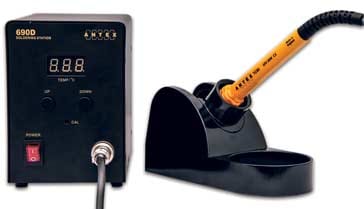

Obviously the main requirement for soldering is the soldering iron itself. There are several different types of soldering iron that can be bought, and the actual iron will depend upon a variety of factors including its specification and the cost.

Soldering irons may be straightforward irons that regulate the temperature by the cooling effect of the air, or they may have thermostats within them to provide the temperature control. Finally at the top of the range, there are what are often termed workstations that consist of a power unit and the iron itself. These provide much higher degrees of temperature control and setting of the temperature to be used.

Additional tools for soldering

In addition to the soldering iron itself, a variety of other tools help. Obviously items like wire cutters, thin nosed pliers and the like. There are also other tools like the "helping hands" that can hold a wire or component in place whilst one hand is used for the soldering iron and another for the other item to be soldered. PCB holders are also very useful when building printed circuit board. The components can be inserted and then held in place whilst the under-side is soldered.

Soldering technology is a key element of the electronics industry. Without solder and soldering technology, the electronics industry would look very different. It provides a unique and very convenient method of connecting electronic components to each other and along with wiring and printed circuit technology it enables circuits to be built and operate reliably.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Construction Ideas & Concepts:

Soldering

SMT component soldering

ESD - Electro-Static Discharge

PCB manufacture

PCB assembly

Return to Constructional Techniques menu . . .