How to Make Loudspeaker Cabinet or Box

Top tips and guidelines on how to design and build a loudspeaker box or cabinet to ensure the best sound is achieved: box material thickness; damping; material to use; and many more.

Loudspeaker Tutorial Includes:

What is a loudspeaker: basics

Moving coil loudspeaker

Loudspeaker enclosures

Loudspeaker repairs

Speaker wire / cable

Additional baffle topics:

Speaker Open Baffle

Infinite Baffle Speaker Cabinet

How to make a loudspeaker box

Upgrading old speaker system

To ensure that a loudspeaker or loudspeaker system operates to its best, it is necessary to have a box or cabinet to enclose the loudspeaker or loudspeakers in some way.

The way that the enclosure or box is made can have a significant impact on its performance, and accordingly making the box in the right way and with the right materials can have a major impact upon the performance.

When considering making a loudspeaker box, or even upgrading an existing one, there are a few hints and tips that can help to ensure that the best performance is obtained.

Making loudspeaker cabinets or boxes - top tips

When making or refurbishing loudspeaker cabinets there are a number of ideas that can be incorporated into the build of the cabinet.

Material for the cabinet: One of the key decisions when making a loudspeaker cabinet, is the material that is used to build the cabinet.

There are many opinions about the best material to use, but most people say not to use wood as it expands and contracts and it can also bend easily, making rigid structure difficult to achieve. As it is key to make the loudspeaker box as rigid as possible, wood is not ideal.

Many companies and people believe that MDF offers an ideal option. It is is very dense and relatively sound absorbent, and it does not flex in the same way as wood.

As loudspeakers for domestic environments, and even studios need to look appealing, it is normal to add a veneer to the MDF and in this way the loudspeaker box will have a good wood finish.

Loudspeaker box thickness: The thickness of the material making up the box is also important. The thicker the material, e.g. MDF out of which the box is made, the better as it will be less prone to vibration. Any vibrations on the panels of the box will interfere with the vibrations or sound coming from the front, and may reduce the performance, especially giving a noticeable reduction in bass response.

The thicker the material that makes the box, the heavier it becomes. There is point where it can be too heavy for convenience. Normally the material used can be 19mm thick, or for more robustness it can be 25mm thick.

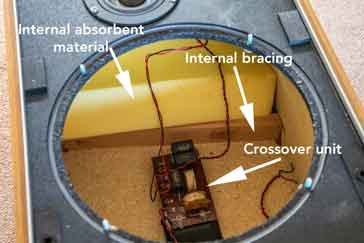

Internal bracing: One of the methods that can be used for improving the rigidity of the loudspeaker box is to add some bracing. Additional members within the box at strategic positions can provide additional rigidity and reduce the level of vibrations.

Care has to be taken when introducing any bracing not to provide large surfaces that can reflect the sound vibrations and add colouration to the reproduction. Normally an extra member to stiffen the centre of a large panel might be considered.

When selecting the material to act as braces, it should be thick enough and "strong" enough not to vibrate and introduce extra resonances. It is important that adding braces can be advantageous, but they must be adequately stiff. MDF is normally a good material to use as it has good strength and also is relatively dead to resonances, but it should also be adequately thick.

If braces are added when a loudspeaker cabinet or box is being designed and made, strengthening can be placed around the box. One approach is to cut a rectangular section that fits into the loudspeaker cabinet, and this has a large hole cut into this. In this way strengthening is provided all around the loudspeaker box. Sadly if bracing is to be retro fitted, this approach can't normally be used, but instead bracing is added where the most vibration is likely to be needed and where it can be physically added.

Damping material: As an alternative or addition to bracing members within the box, sound damping sheets can be added to the panels. These are stuck to the internal panels and serve to absorb the sound and reduce the vibration levels. These are very similar to the panels used in automobiles and even computers to reduce the noise levels.

Internal absorbent material: This material is slightly different to the damping sheets that are stuck to the panels. This material is placed into the loudspeaker enclosure or box and serves to reduce the resonances and generally absorb the sound in the box. Special sound absorbent material is available and it is normally placed into the box filing the space as appropriate.

Loudspeaker box size: The loudspeaker box should be as large as reasonably possible. Normally the box size is specified in terms of litres where 1000 cubic centimetres is a litre, or 1 cubic metre is 1000 litres.

Many good quality loudspeaker boxes are often between 40 and 100 litres, although trying to bound the ideal size is difficult. As the bass response is improved with increased size, typically the larger the possible the better, although this does need to be balanced against the size that the room can accommodate.

Seal the loudspeaker box: If the loudspeaker box is being constructed, ensure that all the edges are securely glued together and there are now ways in which air can escape and let sound out. Typically make sure that all the edges have glu all along the surfaces to be glued.

Use sealing gasket: It is also wise to use a sealing gasket around all the holes, i.e. between the loudspeaker mountings themselves and the font panel of the loudspeaker cabinet. Connector panels can also usefully use a gasket seal around them.

This gasket is normally quite narrow and can be bought from specialist loudspeaker suppliers.Mount the box on spikes: To reduce the vibrations being coupled to the floor, many people mount their loudspeaker boxes on spikes. These spikes as typically conical mounts that fit into special receptacles that can be placed ont e floor. The reasoning is that as these spikes reduce the contact areas, they reduce any vibration transmission.

Warning: When cutting, sanding and shaping MDF, great care must be taken not to inhale the dust as it can damage health. Wear a mask and cut the board outside and not in an enclosed space.

These hints and tips will help with the renovation or building of a loudspeaker enclosure or box and the overall loudspeaker system. Following a few guidelines like these will help to ensure the speaker performance is made as good as it can be for the size, cost and other constraints allowable.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Audio Video Topics:

HDMI

SCART

DisplayPort

DVI

Loudspeaker technology

Headphones & earphones

Bluetooth speakers

Stereo sound

Microphones

Audio compact cassettes

Vinyl record technology

Digital radio

DVB television

Return to Audio / Video menu . . .