Connecting Wire Details

- the basics of electronics wire for electronics wiring including the equivalents between the American AWG wires and metric wires as well as the insulation including PVC wire, PTFE wire and enamelled copper wire.

Home » Electronic components » this page

cables and Wires Tutorial Includes:

Wire / cable types

Connecting wire

Often, when building electronics projects, little thought is given thought is given to the connecting wire. While it is possible to "get away with" almost anything for many projects, it is sometimes necessary to connect the various electronics components using the right wire. For example it is often useful to use coloured connecting wire to indicate such items as electronics wire used for connecting the supplies, signals, and grounds. In this way it is easier to identify the different signals and lines and this reduces the possibility of errors. In addition to this it is sometimes necessary to have connecting wire of a particular size to ensure the connections are made in the right manner. If the wire is too thick it may not be easy to accommodate in some situations, whereas thicker wire may be needed for higher currents of physical strength or robustness in other situations.

Types of electronics connecting wire

Electronics wire for connecting is often categorised by the insulation. The type of insulation is important because it often governs the type of use for which it is suitable.

- Bare copper wire: Wire that is not insulated can be used in a variety of ways. It may be used to correct problems on a printed circuit board where insulation may not be a problem. It may also be used in areas where sleeving may be slid over the wire to protect it from causing shorts, or it may be used in areas where it is not possible to cause short circuits. Although it is possible to use bare copper wire, usually it is pre-tinned to enable easier soldering.

- Enamelled copper wire: This type of copper wire has a form of insulation made from enamel. This is effectively like a varnish over the copper wire. Enamelled copper wire is used in applications such as coils where insulation is required but the thickness of the insulation may be an issue. The enamel is not as robust as other forms of insulation so it is not used where it my be scratched or knocked.

there are some forms of enamelled wire where the insulation or enamel will burn of when being soldered. This enables the wire to be used on circuit boards and removes the need for stripping the wire before connections are made. However care must be taken when using this wire as accidental connections may be made if the insulation is abraded. - PVC wire: PVC wire is the most common form of wire today. Although it is usually termed PVC wire, it should be more correctly termed PVC coated wire as the PVC forms the insulation. The advantage of PVC wire is that it is adequate for most situations and the ends are easy to strip to make connections. However it can melt or in severe cases it can burn when it becomes hot. Also when it is cold, the PVC becomes brittle and can crack if bent.

- PTFE wire: PTFE wire is far more expensive than PVC wire. Like PVC wire, it should be more correctly termed PTFE coated wire. The PTFE insulation is more robust, and can be used over a much wider range of temperatures. However it is much more expensive and it is also much more difficult to strip to expose the bare copper wire for making connections or soldering.

These are the main types of wire that are used, and although there are some other types, these are by far the most widely used.

AWG / Metric wire conversion table

Wire "size" can be measured in a variety of ways. There are three main methods that have been used over the years. SWG or Standard Wire Gauge was widely used some years ago, but now two methods are used. One is AWG or American Wire gauge, and the other is the metric system where wire and cable sizes are measured by their cross sectional area in square millimetres. Where multiple strands are used this can be expressed as the number of strands or a certain wire. As an example seven strands of 0.032 mm wire would be expressed as 7 / 0.032.

For the wires and cables defined under the AWG system, the gauge numbers applied to the wire are for the overall wire whether it is a single strand of a bunch of strands with an equivalent size. This means that the gauge size only determines its overall cross sectional area, and not its physical construction.

The table with approximate equivalents for wires and cables is given below:

| Cross Sectional area sq mm |

AWG | Approximate resistance Ohms / km |

| 0.032 | 32 | 580 |

| 0.051 | 30 | 350 |

| 0.081 | 28 | 230 |

| 0.128 | 26 | 150 |

| 0.163 | 25 | 110 |

| 0.22 | 24 | 76 |

| 0.25 | 23 | 70 |

| 0.32 | 22 | 55 |

| 0.41 | 21 | 44 |

| 0.52 | 20 | 35 |

| 0.75 | 18 | 23 |

| 1.32 | 16 | 15 |

| 2.08 | 14 | 9 |

| 2.5 | 13 | 7 |

| 4.0 | 11 | 4.5 |

While every effort has been made to ensure the correctness of the electronics connecting wire and cable data, no responsibility can be accepted for any errors or the consequences of any errors.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Electronic Components:

Batteries

Capacitors

Connectors

ADC

DAC

Diodes

FET

Inductors

Memory types

Phototransistor

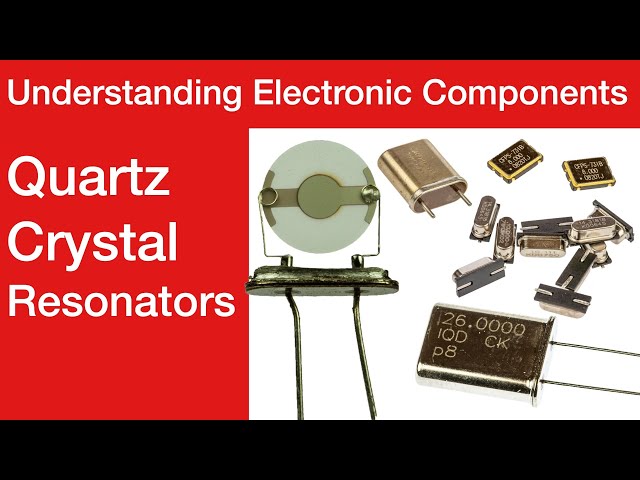

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .