Laser Diode Technology 101: What is it & How it Works

Learn about laser diode technology, including history, construction, & applications - everything you need to know about them from the basics to more advanced concepts.

Home » Electronic components » this page

Laser Diode Includes:

Laser diode basics

Specifications

Other diodes: Diode types

The laser diode is a form of semiconductor diode that generates coherent laser light rather than the more usual incoherent light produced by other sources such as LEDs or other emitters, even though some of these produce a narrow band of frequencies.

Semiconductor laser diode technology is in widespread use today in many areas of the electronics industry where the coherent light produced is essential for the particular applications.

Laser diode technology is now well established, with laser diodes providing a very cost effective, convenient and reliable means of developing coherent or laser light.

Nowadays semiconductor laser diodes are by far the most common method of generating laser light, and the diodes themselves can be obtained quite cheaply.

Laser diode overview

Laser diodes are used in all areas of electronics from domestic equipment, through commercial applications to hash industrial environments. In all these applications laser diodes are able to provide a cost effective solution while being rugged and reliable and offering a high level of performance.

Laser diode technology has a number of advantages:

- Power capability: Laser diodes are able to provide power levels from a few milliwatts right up to a few hundreds of watts.

- Efficiency: Laser diode efficiency levels can exceed 30%, making laser diodes a particularly efficient method of generating coherent light.

- Coherent light: The very nature of a laser is that it generates coherent light. This can be focussed to a diffraction limited spot for high density optical storage applications.

- Rugged construction: Laser diodes are completely solid state and do not require fragile glass elements or critical set-up procedures. Accordingly they are able to operate under harsh conditions.

- Compact: Laser diodes can be quite small allowing for laser diode technology to provide a very compact solution.

- Variety of wavelengths: Using the latest technology and a variety of materials, laser diode technology is able to generate light over a wide spectrum. The use of blue light having a short wavelength allows for tighter focussing of the image for higher density storage.

- Modulation: It is easy to modulate a laser diode, and this makes laser diode technology ideal for many high data rate communications applications. The modulation is achieved by directly modulating the drive current to the laser diode. This enables frequencies up to several GHz to be achieved for applications such as high-speed data communications.

Laser diode background

The name laser comes from the words Light Amplification by Stimulated Emission of Radiation.

Lasers operate because of a phenomenon called stimulated emission that was first postulated by Albert Einstein before 1920. Although a number of media including gases liquids and amorphous solids can be used for lasers the first ones were realised in the 1960s using rubies.

A helium-neon gas laser followed this in 1961 but it was not until 1970 that semiconductor laser diodes were made to run at room temperature by Hayashi.

The development of a semiconductor laser represented the final step in research work that had been undertaken by a number of people and organisations over the years. It had required an in depth study of the properties of Gallium Arsenide, the material that is used as the basis for many laser diodes and much work on the properties of the diode structures.

Today a variety of compound semiconductor materials are used, the choice providing the final output characteristics including the wavelength of the light produced.

Laser diode symbol

The laser diode symbol used for circuit diagrams is often the same one used for light emitting diodes.

Although the use of the same circuit symbol for laser diodes and LEDs might appear to lead to confusion with standard LEDs, the components list will normally remove the possibility of confusion. However it is best to ensure that the laser diode is distinctly highlighted as a laser diode rather than an LED.

This laser diode circuit symbol uses the basic semiconductor diode symbol with arrows indicating the generation and emanation of light.

When used within a circuit, they are often denoted as being a laser diode to distinguish them from other forms of light emitting diode.

What is a laser diode - the basics & how they work

The laser diode is a semiconductor PN junction diode is a form of diode that when it conducts current, it emits a coherent, monochromatic form of light.

Although similar in some ways to a light emitting diode, the way in which light is formed and the type of light emitted is very different to that of an LED.

The term LASER stands for Light Amplification by Stimulated Emission of Radiation and this gives a clue to some of the aspects associated with laser diodes and their properties.

In order to understand laser diodes better, it is necessary to understand the form of light produced.

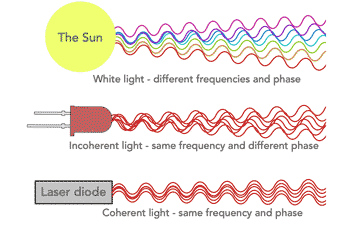

Essentially there are three forms of light emission: white light which consists of all frequencies; narrow band incoherent light, so as that seen through a filter or from something like a single colour LED, etc., and coherent light which is monochromatic and the light remains in a constant phase.

The important aspect of the light produced by a laser is that it is coherent light - having the same phase as well as the same frequency.

The operation of a semiconductor laser diode is characterised by three stages of operation.

Energy absorption: The first requirement for the development of laser light is the injection of energy. This is achieved by passing current into the diode which is effectively a PN junction. A key part of the light generation process occurs as electrons in the crystal lattice absorb energy and pass to a higher energy state to become free electrons leaving holes where the electron had been in the lattice. The electrons stay as free electrons for a short time and then recombine with a hole.

Spontaneous emission : Spontaneous emission occurs as a result of the recombination of electrons with holes. When free electrons recombine with a hole and settle back into the crystal lattice, they move from a higher energy state to a lower energy state. This action releases energy and some of this energy can be converted into light photons. This is the mechanism that occurs within a light emitting diode. The light generated in this way is incoherent, i.e. not the same phase and frequency, although the light is within a aprticaulr part of the spectrum.

Stimulated emission: For diodes to move from being a simple LED to become a laser diode, they need to have a further stage within the overall light generation process. This is achieved by fabricating a partially reflecting surfaces at either end of the structure - these reflect some light but also allow some out. The trapped photons from the reflecting surfaces stimulate those electrons that are already excited to recombine with holes faster than they would normally do. This process results in the release of more photons and these have exactly the same frequency and phase as the initial ones. In this way the coherent light becomes amplified and ultimately some will exit the diode and become the beam of laser light.

The key to the laser diode operation occurs at the junction of the highly doped P and N type regions. In a normal PN junction current flows across the PN junction.

This action can occur because the holes from the p-type region and the electrons from the n-type region combine. With an electromagnetic wave (in this instance light) in passing through the laser diode junction diode junction it is found that the photo-emission process occurs. Here the photons release further photons of light occurs when they strike electrons during the recombination of holes and electrons occurs.

Naturally there is some absorption of the light, resulting in the generation of holes and electrons but there is an overall gain in level.

The structure of the laser diode creates an optical cavity in which the light photons have multiple reflections. When the photons are generated only a small number are able to leave the cavity.

In this way when one photon strikes an electron and enables another photon to be generated the process repeats itself and the photon density or light level starts to build up. It is in the design of better optical cavities that much of the current work on lasers is being undertaken. Ensuring the light is properly reflected is the key to the operation of the device.

Injection lasers and optically pumped lasers

The most common form of laser which was described above is called a Injection laser diode and the original light is generated and then amplified as a laser light beam within the diode.

There is another form of laser diode called an Optically Pumped Semiconductor Laser, OPSL which is much less common. This uses a III-V semiconductor chip as its basis and this acts as an optical gain medium, and another laser which may be an ILD is used as the pump source. The OPSL approach offers several advantages, particularly in wavelength selection and lack of interference from internal electrode structures.

Laser diode structures

There may appear to be many similarities between a light emitting diode and a laser diode, the two are fundamentally different from an operational point of view.

The laser diode is consists of heavily doped n+ and p+ regions. For manufacture it is normal to start with an n+ substrate and then the top layer can be grown onto this.

The doping can be included in a variety of ways, either by diffusion, ion implantation or even deposited during the epitaxy process. A variety of materials can be used for laser diodes, although the most common starting substrates are Gallium Arsenide (GaAs) and Indium Phosphate (InP).

These are known as type III-V compounds because of their places in the chemical periodic table of elements. Whatever material is used, it must be possible to heavily dope it as either a p type or n type semiconductor. This rules out most of the type II-VI materials, leaving the group III-V materials as the ideal option.

Apart from the basic semiconductor requirements, there are a number of optical requirements that are needed to enable the laser diode to operate. It needs an optical resonator. This must occur in the plane of the required light output.

To achieve this the two walls of the laser diode that form the resonator must be almost perfectly smooth, forming a mirror surface from which the light can be reflected internally. One of the walls is made slightly less reflecting to enable the light to come out from the laser diode.

Another requirement is that the two mirror surfaces must be perfectly perpendicular to the junction, otherwise the laser action does not occur satisfactorily. The two other surfaces perpendicular to the one of the required light output are roughened slightly to ensure that the laser action does not occur in this plane as well. In this way a resonant optical cavity is created. Although it is many wavelengths long it still acts as a resonant cavity.

Laser diode applications

Although laser diodes may not be the most commonly seen components when looking at general electronic design, these diodes are used in many products that are in everyday use in many areas:

There is a long list of areas where semiconductor laser diodes form the key element in a particular piece of electronics equipment:

CD / DVD players: The laser diode is the component which generates the coherent light beam needed to scan and write the data from and to the disc. Coherent light is required because of the density of the data on the disc.

Laser printers: From the name it is obvious that this printing technology is based around a laser. The laser is used as the key element in printing the coloured pigment or toner onto the paper.

Bar-code readers: Barcode readers require laser light in order to ensure the correct reading of the bar codes that are printed on a wide variety of products.

Fibre optic communications: Coherent light is required for many fibre optic communications. Using coherent single frequency light ensures that far higher data rates can be sued and lower error rates are experienced.

LIDAR systems: Light based radar systems are becoming more widespread and will be used increasingly in autonomous vehicles to provide detection of other nearby vehicles and objects.

Industrial applications: Lasers, both low and high power semiconductor lasers are used in many pieces of industrial equipment for everything from object detection, barcode and other sensing devices and for precise cutting etc.

There are very many areas where lasers are used to provide a variety different applications. They are often the crucial component in a piece of electronics equipment.

Differences between laser diodes & LEDs

Although laser diodes and LEDs are both forms of diode that emit light, they are fundamentally very different forms of semiconductor diode.

The forms of light that the two forms of diode emit are very different and they are used in very different applications.

| Comparison of Laser Diode vs LED |

||

|---|---|---|

| Characteristic | Laser Diode | LED, Light emitting diode |

| Light emitted | Coherent light | Incoherent |

| Light frequency | Monochromatic | Wider bandwidth based around main frequency |

| Cost | Higher cost | Low cost |

| Junction | Narrow junction | Wide junction |

| Light emission principle | Stimulated emission | Electro-luminescence |

| Response time | Fast response in comparison to LED | Much slower |

Laser diode types

There are several abbreviations that can be seen when looking at laser diodes and these correspond to the various types that can be obtained.

Double heterostructure laser diode : The double hetero-junction laser diode is made up by sandwiching a layer of a low bandgap material with a layer on either side of high bandgap layers. This makes the two hetero-junctions as the materials themselves are different and not just the same material with different types of doping. Common materials for the double heterojunction laser diode are Gallium Arsenide, GaAs, and aluminium gallium arsenide, AlGaAs.

The advantage of the double hetero-junction laser diode over other types is that the holes and electrons are confined to the thin middle layer which acts as the active region. By containing the electrons and holes within this area more effectively, more electron-hole pairs are available for the laser optical amplification process. Additionally the change in material at the hetero-junction helps contain the light within the active region providing additional benefit.

Quantum well laser diode: The quantum well laser diode uses a very thin middle layer - this acts as a quantum well where the vertical component of the electron wave function is quantised. As the quantum well has an abrupt edge, this concentrates electrons in energy states that contribute to laser action, and this increases the efficiency of the system.

In addition to the single quantum well laser diodes, multiple quantum-well laser diodes also exist. The presence of multiple quantum wells improves the overlap between the gain region and the optical waveguide mode.

- Quantum cascade laser diode: This is a form of hetero-junction laser diode which the difference between well energy levels is used to provide the laser light generation. This allows the laser diode to generate relatively long wavelength light - the actual wavelength can be adjusted during fabrication by altering the laser diode layer thickness.

Separate confinement heterostructure laser diode: This form of laser diode has been widely used for the majority of laser diodes since the 1990s. The separate confinement laser diode overcomes the problem that in many other forms of laser diode the thin laser layer is too thin to confine the light effectively. This laser diode overcomes the problem by adding another two layers with a lower refractive index on the outside of the existing ones. This effectively confines the light to within the diode.

- Distributed feedback laser diode: Distributed feedback laser diodes, DFB, are used in forms of telecommunications or data transmission using optical systems. Here the laser diode wavelength is important, but laser diodes are not particularly stable in this respect with wavelength varying with temperature, voltage, ageing, etc.. A diffraction grating is etched close to the p-n junction of the diode to assist in stabilising the wavelength of the generated light signal, This grating acts like an optical filter causing a single wavelength to be fed back to the gain region. The pitch of the grating is set during manufacture, and this only varies slightly with temperature.

- VCSEL: This form of laser diode is a Vertical-Cavity Surface-Emitting Laser diode These are a form of surface emitting laser and they emit the laser radiation in a direction perpendicular to the wafer, delivering a few milliwatts with high beam quality.

- External cavity laser diode: External cavity lasers contain a laser diode as the gain medium only of a longer laser cavity. These lasers are often wavelength-tuneable and they exhibit a small emission spectral line width.

- VECSEL: The VECSEL is a Vertical External Cavity Surface Emitting Laser diode. These are a form of optically pumped surface-emitting external-cavity semiconductor laser, capable of generating multi-watt output powers with excellent beam quality, even in mode-locked operation.

Laser diode reliability and lifetime basics

There are a number of factors which affect the overall laser diode lifetime. While a catastrophic failure is one of the more obvious laser diode failure modes, it is also found that laser diodes degrade over time.

It is found that the forward current which does not contribute to the light generation causes the light emission characteristics to change. One aspect of this is that it takes more current to produce the same level of light. In many circumstances the laser diode life as the time when rises to a given value to attain the same light value - some have defined this as 1.2 times the initial value. This value may be chosen because there is a limit on any automatic power control circuitry in the equipment.

to provide same light output

One of the key factors with the ageing process within laser diodes is the operating temperature. The degradation speed rises exponentially with the operating temperature.

Laser diode catastrophic optical damage, COD

Surge currents in laser diodes can lead to the rapid failure. It is found that in laser diodes that if the current is raised to increase the output optical power, a point is reached where the output power suddenly falls away and irreversible damage is entailed. This form of failure is known as Catastrophic Optical Damage, COD.

COD occurs when high output levels cause a short melting of part of the laser diode edge. At this point crystal defects form.

The very nature of laser diodes makes them susceptible to damage. Many operate at very high speeds - often in excess of 1GHz and in addition to this they are low voltage devices - around 2 volts. The combination of these two factors means that they are very susceptible to dame by surges.

In order to prevent the possibility of COD, it is necessary to protect the laser diode from surges. Turn on of general supply surges can provide short lived spikes that can easily damage the laser diode and cause failure.

It is also found that even if the laser diode is not completely destroyed by a surge because it may not be of sufficient magnitude to completely destroy the device, a general deterioration may be caused, causing a shortening of the life. Accordingly it is necessary to run laser diodes well within their ratings to ensure their lifetime is maintained.

Laser diode circuit design

The electronic circuit design for laser diodes must be undertaken with care. It is very easy for them to be damaged if the correct design techniques are not used.

As the diode follows the general V-I curve format for a semiconductor diode, they are often driven using a sophisticated form of constant current driver. This will enable stable and predictable level of current to be provided.

Very sophisticated designs can also incorporate device temperature and output sensing to provide additional feedback.

There are generally two approaches that are often used:

Automatic Current Control, ACC: In its simplest form, this type of driver for a laser diode is a constant current source. It is the simplest form of driver and will provide the required control for many different circuit design applications

Many designs are available using drivers based around integrated circuits such as the LM317 or similar. These can be designed to give the required fixed level output, or they can even be amde variable should this be required, but limited so that the maximum current is not exceeded.

The very basic circuits do not provide any form of temperature compensation, and can sufficiently work well for many low end applications. However for a simple form of diode based temerpature compensation adds a little further improvement in performance and protection.

Automatic Power Control, APC: This type of laser diode driver circuit is far more sophisticated, using various forms of feedback to ensure a constant output and the correct drive conditions as well as ensuring there is sufficient protection provided.

These circuits often incorporate aspects such as photo-diode detection of the output level, full thermal management of the diode temperature, over-current / over-voltage protection, and possibly level control.

These electronic circuit designs are more complicated and involve more electronic circuit design as well as more electronic components, yet they provide better performance as the output is optimised and constant. These might be used for industrial or commercial applications, possibly in laser printers, fibre optic communications and the like.

When designing a driver circuit for a laser diode it is necessary to ensure that the correct protection is incorporated. Transients, and even overshoot spikes can result in damage to the devices, so it is necessary to ensure that these cannot occur.

Careful design of the circuits is required to ensure that the diode is adequately protected and this will ensure a reliable lifetime.

It is also necessary to ensure that the power supply gives a constant output. Laser diodes are current driven and current sensitive semiconductors. Any change in the drive current will result in a change in the output light wavelength and output power.

Accordingly it is necessary to ensure that noise, voltage or current drift, and induced transients are minimised as these will affect the performance of the device.

The laser diode is now well established, and used in a wide variety of applications. Although not nearly as cheap as many other forms of diode, laser diodes are still produced in vast quantities and at a relatively low cost, as demonstrated by the fact that laser diodes are even used in the light pencils used for illustrating overhead projector slide presentations. At the other end of the market, laser diodes for use in optical communications systems have been shown with data rates in excess of 20 Gbits per second. With performance levels in this region, they are being used increasingly in many communications applications.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Electronic Components:

Batteries

Capacitors

Connectors

ADC

DAC

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .