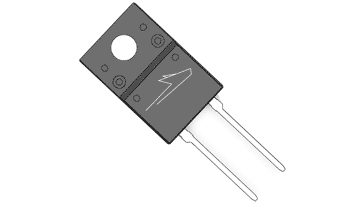

Silicon Carbide, SiC Schottky Diode

Silicon carbide, SiC Schottky diodes are being used in an increasing number of areas to provide significantly improved performance over equivalent silicon diodes.

Home » Electronic components » this page

Schottky Barrier Diode Tutorial Includes:

Schottky barrier diode

Schottky diode technology

Schottky diode specifications

Schottky diode power rectifier

Silicon carbide Schottky diode

Diode types

Diode component data:

PN junction diode data

Schottky diode data

Silicon carbide, SiC Schottky diode data

Silicon carbide diodes or SiC diodes are being used increasingly. Normally in the form of a Schottky diode, they tend to be used for power applications.

In these applications, the silicon carbide diodes are able to provide significant improvements in performance, improving the efficiency of power electronic circuit designs.

In addition to this, the voltages at which these silicon carbide Schottky diodes can operate is significantly higher than normal silicon Schottky diodes.

As a result, silicon carbide electronic components are being used increasingly as they offer a very cost effective solution to many electronic circuit designs, especially as they enable many of the new power efficiency requirements to be met more easily.

In view of the increased usage of SiC diodes,, costs are falling and this makes the case for using them far more compelling than it would have been in the early days of these devices when the technology was relatively new.

These didoes are available in many formats from leaded and even bolt-on styles to surface mount diodes - these surface mount diodes are used in many areas including power supply technology where high efficiency levels and small form factors are needed.

What is a silicon carbide, SiC, Schottky diode

Although silicon carbide may not normally be associated with semiconductor devices, it has in fact been used for many years. In the days of crystal radio sets back in the 1920s and even a bit earlier in some cases, silicon carbide or carborundum as it was known, was used with Cat's Whisker radio detectors. These then became the first widely used silicon carbon or SiC diodes.

The material is now being widely used with power devices, because one if its particular attributes is the very high breakdown electric field strength and this enables the fabrication of higher voltage diodes. For silicon itself, the maximum voltage for Schottky diodes is around 200 volts, although this is very dependent upon the actual device.

Video: Silicon carbide Schottky Diodes: understanding them

However for silicon carbide, SiC diodes with reverse breakdown values well in excess of 1kV are available - some have specified values up to 1.5kV. This is a distinct advantage, enabling them to be used in many more electronic circuit designs.

Like silicon Schottky diodes, the silicon carbide Schottky diode uses the fact that in the ON state, i.e. forward bias, electrons can cross the barrier to enable current to flow. This means that when the forward voltage is greater than about 0.2V, then current will start to flow.

However the issue with Schottky barrier diodes is that if the reverse voltage becomes too high, then there will be breakdown across the barrier and the diode can be damaged.

It is for this reason that the maximum reverse voltages for any silicon Schottky diode is generally limited to a maximum of about 200 V or even much less but dependent upon the actual diode. Fortunately for silicon carbide versions the reverse voltage limit can extend above a kilovolt or more, dependent upon the actual diode.

Note on Silicon Carbide:

Silicon carbide is a material that is known for its hardness, but it is also being used as a semiconductor providing devices that are able to offer new levels of performance, especially within power electronics designs.

Read more about Silicon Carbide.

In terms of their performance, silicon carbide Schottky diodes have a lot to offer for new electronic circuit designs - particularly those associated with power systems as they provide significant performance enhancements in terms of better switching performance, higher efficiency and better levels of power density as well as reducing the overall costs for the finished electronic circuit design.

In terms of their actual performance, silicon carbide diodes specifications detail that they provide low forward voltage drop, high level of current stability, high surge voltage withstand capability and positive temperature co-efficient.

In fact another key feature of silicon carbide Schottky diodes is that they provide a very fast recovery time. This factor enables them to provide high switching speeds and as they can run at high frequencies they can use smaller magnetic and other passive components. This reduces the size of the overall electronic designs for these units.

The diodes also provide a low level capacitance when reverse biassed which is important where high frequencies and speeds are required.

All of these features mean that silicon carbide Schottky diodes are being widely used in many power converters and systems. They are being used in solar PV inverters, general power supply circuit designs, electric vehicle chargers, and many other automotive and power related circuits and designs.

The SiC diodes are available in a variety of packages: leaded devices as well as bolt-on where power levels are high. Surface mount SMD diodes are also available. These SMD diodes are very useful in many switch mode power supplies and voltage converters where efficiency levels need to be high and space needs to be small.

SiC diode structure

The structure of silicon carbide Schottky diode is very similar to that of a silicon version.

A metal to silicon carbide junction is formed by depositing a metal contact onto the semiconductor material, and as a result of this junction format, only electrons flow, rather than the situation in a traditional PN junction where both electrons and holes flow (but in opposite directions).

Although there are both silicon and silicon carbide versions of Schottky diodes and both are able to provide low turn on voltage and fast operation, the SiC versions of the devices are able to provide a much higher reverse breakdown.

Silicon carbide diode properties

It is worth looking at the various specifications for silicon carbide diodes in a little more detail to find out exactly how they can best be used.

Their properties mean that they are ideally suited for many power related electronic circuit designs, where they can give a significant improvement in many respects when compared to the more traditional silicon based Schottky diodes.

Forward voltage drop: The advantage of a Schottky diode is that it provides a much lower forward voltage drop than a traditional PN junction diode. While the turn-on voltage for a Schottky diode is lower, than that of a PN junction diode, it must be remembered that resistive effects will also be present and this will mean that as the current rises, so too will the forward voltage drop.

The forward voltage drop is also temperature dependent, rising with temperature. Therefore keeping the diode cool-ish can help reduce losses due to resistance and power dissipation will be lower.

Operational temperature: While the resistive losses increase with temperature, it is still possible to run silicon carbide diodes at a higher temperature than silicon ones and retain the same level of reliability. Temperatures of 170°C are often quoted in the data-sheets for these diodes.

Maximum reverse voltage: While silicon Schottky diodes may only have a maximum reverse breakdown voltage of around 200 volts, the value for silicon carbide diodes is very much higher. Dependent upon the actual diode in question values of 1.2kV and in some cases even 1.6kV have been seen in data sheets.

This much higher reverse voltage enables them to be used in many power supply related circuit designs where the silicon Schottky diodes would not be appropriate.

Leakage current: While Schottky diodes are known for having a high level of leakage current, that of a silicon carbide diode is very much lower.

Recovery time: As the only charge carriers within the junction area of the diode are electrons, this means that the recovery time for the diode is virtually instantaneous. This makes these diodes a very attractive proposition in switching circuits, and in particular within switch mode power supplies.

Thermal conductivity: Silicon carbide has a high level of thermal conductivity and this means that it can conduct heat away from the device more effectively than silicon, meaning that high levels of current can be carried.

High current density: Silicon carbide provides a high level of current density. This means that a junction (or other form of device) can carry a higher level of current for a given junction size. Devices for high levels of current can be surprisingly small.

In essence, when compared to silicon devices, silicon carbide uses energy more efficiently. The combination of better thermal conductivity, current density and higher breakdown voltage as wella s other aspects of the operation of silicon carbide devices means that they can be used for much higher performance units and within a smaller space.

Typical silicon carbide Schottky diode specifications

The specifications for silicon carbide devices vary quite widely dependent upon the particular device in question. There are many different SiC diodes addressing a number of different circuit design arenas.

However it can sometimes be helpful to look at the specifications of a particular device to gain a feel for sort of performance that these devices can provide.

The device given below is described as a general purpose 1.2kV, 15A SiC diode.

| OnSemi FFSH15120A Specifications |

||

|---|---|---|

| Symbol | Parameter | Value |

| VRRM | Peak Repetitive Reverse Voltage | 1200V |

| VF | Forward Voltage | 1.45V typical @ IF=15A @ 25°C 1.7V typical @ IF=15A @ 125°C 2.0V typical @ IF=15A @ 175°C |

| IR | Reverse Current | 200µA max @ VR = 1200V @ 25°C 300µA max @ VR = 1200V @ 125°C 400µA max @ VR = 1200V @ 175°C |

| C | Total capacitance | 936pF for VR = 1V f = 100kHz 86pF for VR = 400V f = 100kHz 68pF for VR = 800V f = 100kHz |

| EAS | Single Pulse Avalanche Energy | 145mJ |

| IF | Continuous Rectified Forward Current @ TC < 159°C | 15A |

| IF | Continuous Rectified Forward Current @ TC < 135°C | 26A |

| IFMAX | Non-Repetitive Peak Forward Surge Current @ 25°C & 10µs | 920A |

| IFSM | Non-Repetitive Forward Surge Current half sine pulse of period 8.3ms | 115A |

| PTOT | Power Dissipation @25°C | 283W |

| PTOT | Power Dissipation @150°C | 47W |

| TJ, TSTG | Operating & storage temperature | -55 - +175°C |

Silicon carbide or SiC Schottky diodes are being used increasingly in many new electronic circuit designs. They are particularly useful in power supply design where the speed of these SiC diodes can enable higher frequencies to be used more efficiently. This brings much higher overall efficiency levels as well as enabling the circuits to be made much smaller. Both of these facts reduce the cost of manufacture.

In view of their performance, silicon carbide diodes are now being used in a variety of applications including: PV solar cell systems, electric vehicle power systems, power rectifier circuits, industrial power and even in low power radio frequency detectors.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Electronic Components:

Batteries

Capacitors

Connectors

ADC

DAC

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .