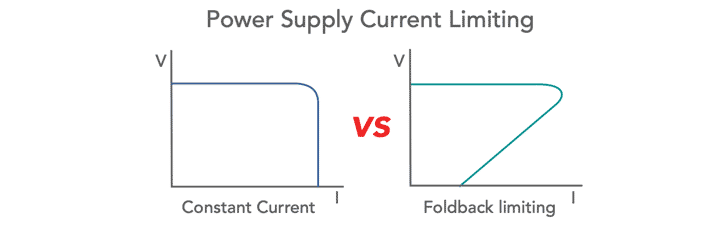

Comparing Constant Current and Foldback Current Limiting: Differences, Advantages, and Disadvantages

Constant current and foldback are forms of current limiting used in power supplies and regulators, with different characteristics that make them applicable for different situations

Linear Power Supply Circuits Primer & Tutorial Includes:

Linear power supply

Shunt regulator

Series regulator

Current limiter

Constant current vs foldback limiting

78** series regulators & circuits

LM317 voltage regulator & circuits

LDO, low dropout regulators

See also:

Power supply electronics overview

Switch mode power supply

Capacitor smoothing

Over-voltage protection

PSU specs

Digital Power

Power management bus: PMbus

Uninterruptible power supply

When looking at regulators and power supplies, it is always good practice to incorporate some form of current limiting into the regulator.

However there are two main types of current limiting, and the choice of the best type may not always be obvious

Current limiting plays a crucial role in protecting circuits and components from additional damage resulting from overloads, short circuits, or excessive current draw.

Without proper safeguards, excessive current can lead to overheating, component failure, or even fire hazards.

Two prominent techniques for implementing current limiting are constant current limiting and foldback current limiting (sometimes referred to as "holdback" in older literature, though foldback is the standard term).

These methods are essential in linear power supplies, voltage regulators, and various electronic systems where stable power delivery is paramount.

Types of current limiting

There are two main techniques used in current limiting:

Constant current limiting: Constant current limiting maintains a fixed maximum current output when an overload occurs, allowing the voltage to drop accordingly to keep the current constant. This approach is straightforward and widely used in basic power supply circuits.

Foldback current limiting: This goes a step further by not only capping the current but also reducing it progressively as the output voltage decreases during a fault condition. This "folding back" of the current helps minimise power dissipation and enhances protection.Understanding the differences between these techniques is vital for engineers and designers.

The importance of current limiting cannot be overstated. In power supplies, overloads can occur due to faulty loads, accidental short circuits, or startup surges from devices like motors or incandescent lamps. Without limiting, the power dissipation in pass elements—like transistors—can exceed safe limits, leading to thermal runaway.

Constant current and foldback address this differently: the former priorities ease of implementation, while the latter focuses on reducing stress during prolonged faults. As we proceed, we'll break down each method's operation, highlighting key differences and weighing their pros and cons to guide informed design choices.

Understanding constant current limiting

Constant current limiting is one of the simplest and most common forms of overcurrent protection in power supplies.

In this technique, the power supply operates normally until the output current reaches a predetermined maximum threshold, often set slightly above the rated full-load current.

Once this limit is hit, the circuit clamps the current at that constant value, allowing the output voltage to decrease proportionally as the load resistance drops.

This ensures that the current does not exceed the safe level, protecting the supply and connected devices.The basic mechanism involves a sense resistor placed in series with the output path.

As current flows through this resistor, it generates a voltage drop proportional to the current (via Ohm's Law: V = I * R). This voltage is monitored, typically using a comparator or transistor-based circuit.

When the drop reaches a reference voltage—such as the base-emitter junction voltage of a transistor (around 0.6V for silicon)—the circuit intervenes by reducing the drive to the pass transistor, effectively limiting the current.

This method is prevalent in linear regulators like the LM317, where internal circuitry provides constant current limiting. For instance, if the rated current is 1A, the limit might be set to 1.2A. Under normal operation, voltage remains stable; during overload, voltage drops while current stays at 1.2A.

Advantages and disadvantages of constant current limiting

It is worth summarising both the advantages and the disadvantages associated with constant current limiting.

Advantages:

Simplicity and Low Cost: Requires minimal components—often just a resistor and diodes or transistors—making it easy to integrate into basic designs without significantly increasing complexity or cost.

Automatic Recovery: Once the overload is removed, the supply returns to normal operation without manual intervention, ideal for transient faults.

Predictable Behaviour: Provides a clear, fixed current ceiling, which is straightforward for testing and ensures consistent protection across varying loads.

Suitability for Certain Loads: Works well with constant-power loads or those with predictable current draws, as it doesn't reduce current further during faults.

Disadvantages

High Power Dissipation: During a short circuit, the full limited current flows while voltage is near zero at the output, but the input voltage remains high. This causes maximum power dissipation (P = V_input * I_limit) in the pass transistor, necessitating larger heatsinks or more robust components to handle the heat.

Potential for Damage in Prolonged Faults: If the fault persists, continuous high dissipation can lead to thermal failure, even if the current is limited.

Inefficiency with Severe Overloads: Doesn't adapt to the severity of the fault; the current remains high even in dead shorts, risking secondary damage like fire in the load.

In summary, constant current limiting is great for the more straightforward applications but falls short in many scenarios demanding robust thermal management.

Understanding foldback current limiting

Foldback current limiting builds on the constant current approach but actually reduces current further as the output voltage drops during an overload.

This "foldback" mechanism a progressively reduces the current to a fraction of the maximum. Often it may be less than 30% of the full output. This protects the power supply by minimising power dissipation.

The circuit typically includes additional resistors and a transistor for sensing both current and voltage.

In ICs like the LT3042, foldback is internal, activating when the input-output differential exceeds 12V. Under normal load, full current is available; in a short, current drops significantly, keeping the transistor cool.

Advantages and disadvantages of foldback current limiting

Advantages

Reduced Power Dissipation: By lowering current in faults, it keeps dissipation low (e.g., P = V_input * I_reduced), allowing smaller transistors and heatsinks, and preventing overheating.

Better Component Protection: Enhances SOA utilisation, reducing stress and extending component life; ideal for high-power applications.

Fire and Safety Benefits: Lower current in shorts minimises heat in the load, reducing fire risks.

Efficiency in Linear Supplies: Commonly integrated into regulators, adding little cost while providing superior protection over constant current.

Disadvantages

Increased Complexity: Requires more components (e.g., extra transistors and resistors), complicating design and potentially raising costs slightly.

Hysteresis and Lockout Issues: May not recover automatically if the load draws constant current; could "latch" in low-current mode, requiring a reset or load increase.

Incompatibility with Certain Loads: Struggles with nonlinear loads like lamps or motors that have high inrush currents, potentially preventing startup.

Design Limitations: High foldback ratios demand higher input voltages and are impractical for low-voltage regulators; accuracy can vary, needing additional tweaks.

Foldback current limiting is ideal in applications where thermal efficiency is key but care is needed to ensure that the load is right.

Key differences between the formats

The main difference between constant current and foldback limiting is with the response to overload severity.

Constant current limiting enforces a fixed current cap, with voltage dropping but current unchanging, leading to high dissipation.

Foldback, however, dynamically reduces current as voltage falls, dropping it to well below the current that the constant current supply would provide.

In terms of the circuit design, a constant current limiter used very basic sensing, while foldback adds voltage feedback.

| Comparative Advantages and Disadvantages or Constant Current and Foldback Limiting |

||

|---|---|---|

| Aspect | Constant Current | Foldback |

| Cmplexity | Low (fewer components) | Higher (requires more components) |

| Power dissipation during overload | Higher | Lower (reduces as voltage drops) |

| Recovery | Automatic | A few circuits can require reset |

| Cost / size | Lower component count, but needs needs larger heatsinks, so overall cost can be higher despite being less complex. | Higher component count may increase component count cost, but heatsinks and other elements may not need to dissipate so much heat, so overall cost may be lower. |

| Protection level | Basic, provides fixed maximum current | More advanced and adapts maximum current to overload degree |

| Load compatibility | Good | May not be appropriate for all loads, especially those requiring large inrush current |

Applications in practice

Constant current limiting is ideal for bench power supplies, LED drivers, and SMPS where simplicity matters.

Foldback is preferred in high-reliability linear supplies, RF circuits, and some IC regulators where it provides better thermal management.

However for foldback limiting the load must be compatible to enable it to function correctly.

In summary, constant current limiting offers a straightforward, cost-effective solution for basic protection, but its high dissipation limits its use in demanding applications. Foldback current limiting, with its adaptive reduction, provides superior safety and efficiency, though at the expense of complexity and potential compatibility issues.

The choice depends on the application's needs: opt for constant current in simple setups and foldback for robust, heat-sensitive designs.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Circuits & Circuit Design:

Op Amp basics

Op Amp circuits

Power supply circuits

Transistor design

Transistor Darlington

Transistor circuits

FET circuits

Circuit symbols

Return to Circuit Design menu . . .