What is a Lithium Polymer Battery

The term, lithium polymer is applied to many lithium ion batteries, so what is the difference and is their performance any better - lithium ion vs lithium polymer

Home » Electronic components » this page

Lithium Ion Battery Includes:

Li-ion technology

Types of lithium ion battery

Lithium polymer battery

Li-ion charging

Li-ion advantages & disadvantages

How to preserve lifetime of lithium ion batteries

Specific tips for preserving smartphone battery lifetime

Battery Technology Includes:

Battery technology overview

Battery definitions & terms

Zinc carbon

Alkaline

Zinc air cells

NiCad

NiMH

Li-ion

Lead acid

The term lithium polymer battery appears in the marketing and product descriptions for a variety of lithium ion batteries.

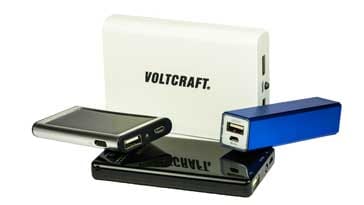

Some power bank batteries are described as lithium polymer and there are differences between the more traditional lithium ion and the more niche lithium polymer batteries.

It is often necessary to compare the performance of lithium ion vs lithium polymer and balance the advantages and disadvantages of each type. It may be for a new equipment design or even when buying a new power bank.

If there are differences in the technology, what at lithium ion batteries, and also what are the differences in performance.

What is lithium polymer technology

There are many terms that are used when looking at lithium polymer and even lithium ion batteries. The industry literature often refers to cylindrical and prismatic cells as using the traditional lithium ion technology, and lithium polymer, lithium poly or even pouch batteries for the lithium polymer technology.

In terms of the basic technology, the lithium polymer battery differs from other forms of lithium ion battery in terms of the electrolyte that it uses in this case it is a form of polymer.

The modern lithium polymer electrolytes use a gel and this enables good conductivity at room temperature. Also most of these batteries use a micro-porous separator.The micro-porous separator is needed with the lithium polymer battery instead of the more usual porous separator used with standard types.

The lithium polymer approach can be used with most lithium ion battery technologies: Lithium cobalt, lithium phosphate, lithium manganese, etc. and in this respect lithium polymer technology is not considered to be a different battery technology, but an enhancement to the types of lithium ion battery already available.

In this way the same anode and cathode materials are used, the only difference is the electrolyte and separator, although the same amount of electrolyte is normally used.

The charge and discharge characteristics for the lithium polymer cells are identical to the standard types and therefore the usual charging mechanisms can be used. Often for items like power banks, etc, USB power sources are used, but the internal charging electronics hardware controls the process - the same circuitry can be typically be used.

For lithium polymer batteries and cells, different manufacturing approaches are employed. Traditional lithium ion batteries mainly use a cylindrical cell configuration or a box configuration known as 'prismatic' cells.

Lithium polymer cells use a foil pouch type of format, which has been described as being similar to chewing gum packages. These can be made very much slimmer than the more traditional ones. This is very attractive for many manufacturers who are always seeking to have slimmer equipment; laptops, phones, etc.

The lithium polymer batteries use a foil type case and laminated sheets within the battery. This enables the batteries to be made much lighter - in facts there is often a weight saving of around 20% or more.

The construction techniques used for the lithium polymer batteries also enable them to be made in a variety of shapes and this is very attractive for mobile phone and laptop manufacturers who may need odd shaped batteries to fit into their very tightly packed equipment.

Lithium ion vs lithium polymer

When selecting a lithium ion battery there may be an option of a standard lithium ion battery or a lithium ion one. For most domestic or personal applications, this can apply to power banks where the type of battery is mentioned in the specification, and it can be wondered which option will be best.

For manufacturers of equipment like laptops, mobile phones and other similar equipment, there are many points to consider when choosing between traditional lithium ion and lithium polymer.

Lithium polymer battery

- Can be made with a very slim outline.

- Can be made in a variety of shapes and outlines.

- Low weight

- Higher energy density for given weight (WH/kg)

- Cost of manufacture now becoming lower.

- Bendable batteries available.

- Slightly higher top usage temperature.

Traditional lithium ion battery

- Higher energy density for given volume (WH/l)

- More widely available.

- Cylindrical version offers lowest cost per WH.

In some respects the differences can be relatively minor and may not be important for some users, but when comparing lithium polymer vs lithium ion batteries, the differences may be important.

Lithium polymer batteries offer some advantages over the more traditional lithium ion battery technologies. In most respects, the polymer version of a battery gives a slight improvement in performance, but also the cost is slightly more.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Electronic Components:

Batteries

Capacitors

Connectors

ADC

DAC

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .