Silicon vs Silicon Carbide MOSFETs: is the silicon MOSFET dead?

With the introduction of silicon cabide, SiC MOSFETs, what are their respective advantages and is the traditional silicon device outdated and no longer to be used?

Home » Electronic components » this page

FETs, Field Effect Transistors Includes:

FET basics

FET specifications

JFET

MOSFET

Dual gate MOSFET

Power MOSFET

MESFET / GaAs FET

HEMT & PHEMT

FinFET technology

IGBT

IGBT vs MOSFET - which is better?

Silicon carbide, SiC JFET

Silicon carbide, SiC MOSFET

Silicon carbide vs silicon MOSFETs

GaN FET / HEMT

FET component data:

MOSFETs

SiC MOSFETs

GaN FETs

IGBTs

For decades, Silicon, Si, has reigned supreme as the backbone of the semiconductor industry.

However, as our demands for power efficiency, electric vehicle range, and smaller power supplies have grown, the industry has looked toward "Wide Bandgap" or WBG materials.

The battle between the traditional Silicon MOSFET and the Silicon Carbide (SiC) MOSFET is one of the most significant shifts in modern power electronics.

This article explores the unique characteristics of both, compares their performance, and highlights where each component truly shines.

The Silicon (Si) MOSFET: The Industry Workhorse

The traditional power MOSFET (Metal-Oxide-Semiconductor Field-Effect Transistor) is a unipolar device, meaning it relies on a single type of charge carrier (electrons for N-channel) to conduct current.

It is worth noting the key characteristics of silicon devices.

Voltage-Controlled Switching: Unlike older bipolar transistors, MOSFETs are voltage-controlled, offering a very high input impedance that makes them relatively easy to drive.

High Switching Speed: Because they do not suffer from "minority carrier injection," Si MOSFETs can turn on and off in the nanosecond range.

Thermal Stability: Si MOSFETs have a positive temperature coefficient; as they get hotter, their resistance increases, which naturally helps prevent thermal runaway when devices are used in parallel.

The primary drawback of standard Silicon is its breakdown voltage. As you design for higher voltages, the "On-Resistance" of a Silicon MOSFET increases exponentially.

To handle high voltages, the device must be physically larger, which increases parasitic capacitance and slows down switching speeds.

This effectively caps the efficiency of Si MOSFETs in high-voltage applications, typically around 600V.

The Silicon Carbide (SiC) MOSFET: The High-Voltage Challenger

Silicon Carbide is a compound of silicon and carbon that falls into the "Wide Bandgap" category.

In simple terms, it takes much more energy to move an electron from the valence band to the conduction band in SiC than it does in standard Si.

Like the silicon devices, it is worth noting the key characteristics of silicon cabide.

High Breakdown Field: SiC can withstand an electric field about ten times higher than Silicon. This allows the device to be much thinner for the same voltage rating, which drastically lowers the RDS(on).

Exceptional Thermal Conductivity: SiC moves heat roughly three times more efficiently than Silicon. This allows engineers to use smaller heatsinks or even eliminate active cooling in some designs.

High-Temperature Operation: While Silicon begins to fail or become unstable at temperatures above 150°C, SiC can theoretically operate at much higher junctions, often limited only by the packaging rather than the semiconductor itself.

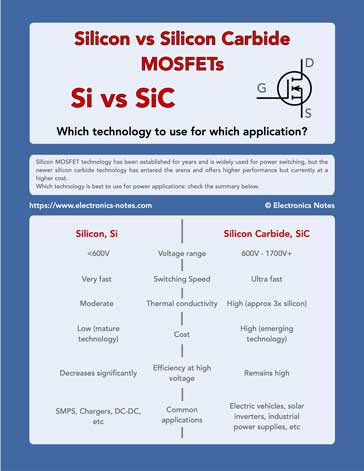

Direct Comparison: Si vs. SiC

To understand which to choose, we must look at the technical trade-offs that define their performance in a circuit.

• Switching Losses and Frequency

Silicon MOSFETs are fast, but SiC MOSFETs are "supercharged". Because SiC devices are thinner and have lower parasitic capacitance, they can switch at significantly higher frequencies with lower losses.

Silicon, Si: Excellent for frequencies in the hundreds of kHz at low voltages.

Silicon carbide, SiC: Can maintain high efficiency at higher voltages and frequencies where Si would simply overheat.

• Conduction Losses

Conduction loss is determined by the formula P = I2 x RDS(on).

- At low voltages, Si MOSFETs are incredibly efficient because their resistance is minimal.

- At high voltages (above 600V), SiC MOSFETs provide a much lower RDS(on) for a given chip size, meaning they waste far less energy as heat.

• System Size and Weight

Because SiC can switch at higher frequencies, the passive components (inductors and capacitors) in a power supply can be much smaller. This leads to advantages for the complete unit: even if the SiC transistor is more expensive, the total size, weight, and cost of the cooling and magnetics may decrease resulting in overall cost reductions.

| |

||

|---|---|---|

| Feature | Silicon MOSFET | Silicon Carbide MOSFET |

| Typical voltage range | < 600V | 600V to 1700V+ |

| Switching Speed | Very fast | Ultra fast |

| Thermal conductivity | Moderate | High (approx 3x Silicon) |

| Cost | Low (Mature tech) | High (Emerging tech) |

| Efficiency at High V | Decreases significantly | Remains High |

Click for larger version

Summary

The choice between Silicon and Silicon Carbide ultimately comes down mainly to the operating voltage and the budget.

If the design operates below about 250V - 600V, Silicon MOSFETs offer a mature, reliable, and inexpensive solution that is hard to justify replacing.

However, if the operating voltage rises into the 600V to 1700V territory Silicon Carbide is the superior technology that will define the next generation of power electronics. These voltags are often found with EVs and green energy systems.

Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Electronic Components:

Batteries

Capacitors

Connectors

ADC

DAC

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .