MOSFET vs. IGBT – Understanding the Giants of Power Electronics

IGBTs and MOSFETs are both big players in power electronics design arena these two types of device can be considered as rivals and its necessary to select the best option for the given circuit.

Home » Electronic components » this page

FETs, Field Effect Transistors Includes:

FET basics

FET specifications

JFET

MOSFET

Dual gate MOSFET

Power MOSFET

MESFET / GaAs FET

HEMT & PHEMT

FinFET technology

IGBT

IGBT vs MOSFET - which is better?

Silicon carbide, SiC JFET

Silicon carbide, SiC MOSFET

GaN FET / HEMT

FET component data:

MOSFETs

SiC MOSFETs

GaN FETs

IGBTs

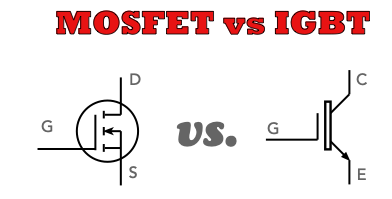

For power electronics electronics design, two semiconductor technologies dominate the landscape: the power MOSFET, Metal-Oxide-Semiconductor Field-Effect Transistor, and the IGBT, Insulated Gate Bipolar Transistor.

While they might look identical in their TO-220 or TO-247 packages, their internal architectures and behaviours are vastly different.

Choosing the appropriate one for the particular design will ensure that the circuit and system can operate with the best performance and as efficiently as possible

This guide breaks down the physics, the trade-offs, and the specific applications where each device excels and shines.

The Core Architectures: How They Work

To better understand the advantages and disadvantages of each type of device, it is necessary to summarise the technology used and how they work.

Power MOSFET: high speed operation

A MOSFET is a unipolar device, meaning it relies on a single type of charge carrier (electrons in an N-channel, holes in a P-channel).

It acts like a voltage-controlled switch. When you apply voltage to the gate, it creates a channel for current to flow.

Key Characteristic: Because there is no "minority carrier injection," the MOSFET can turn on and off incredibly fast.

The Downside: As the voltage rating of a MOSFET increases, its "On-Resistance" (R_{DS(on)}) increases exponentially. This makes high-voltage MOSFETs less efficient at carrying high currents.

IGBT: the heavy lifter

The IGBT is a hybrid device. It combines the easy-to-drive input of a MOSFET with the high-current, high-voltage capabilities of a Bipolar Junction Transistor, BJT. It is fundamentally a bipolar device.

Key Characteristic: It uses "minority carrier injection" to flood the device's drift region with charge, which drastically reduces the voltage drop across the device even at very high currents.

The Downside: Those same minority carriers take time to "recombine" when you turn the device off. This leads to a "tail current," which limits how fast the IGBT can switch.

Key Performance Metrics

When comparing these two electronic component types, it is necessary to look at four main specifications that determine their performance.

Switching Speed and Frequency

- MOSFETs are the clear winners here. They can easily operate in the hundreds of kilohertz (kHz) or even megahertz range. This allows for smaller inductors and capacitors in power supplies.

- IGBTs are generally limited to frequencies below 20–50 kHz. While modern "fast" IGBTs exist, they still can't attain the high speed of a MOSFET.

Conduction Losses

- MOSFETs follow Ohm’s Law. The power loss is P = I^2 \times R_{DS(on)}. At low voltages and currents, this resistance is very low, making them highly efficient.

- IGBTs have a relatively constant V-I characteristic. There is a "threshold" voltage (typically around 0.7V to 2V) that must be overcome. At high currents, the IGBT's fixed voltage drop is much more efficient than the MOSFET's rising resistance.

Voltage Ratings

- MOSFETs are typically the go-to for applications under 600V. While 1000V+ MOSFETs exist, they are often expensive and have high resistance.

- IGBTs are the kings of high voltage, commonly used in applications from 600V to 6500V.

Thermal Stability

- MOSFETs have a positive temperature coefficient. As they get hotter, their resistance increases. This is actually a good thing for paralleling devices, as the hotter device will naturally "push" current to its cooler neighbors.

- IGBTs (especially older ones) can have a negative temperature coefficient, which can lead to "current hogging" and thermal runaway if not carefully managed.

Comparison Table: At a Glance

It is worth tabulating the different features and aspects of IGBTs and MOSFETs to see what their respective advantages and disadvantages are.

| Comparison of MOSFET & IGBT |

||

|---|---|---|

| Feature | MOSFET | IGBT |

| Drive type | Voltage controlled | Voltage controlled |

| Input impedance | Very high | Very high |

| Switching speed | Very fast (~nanoseconds) | Moderate (~microseconds) |

| On-state voltage drop | High at high current levels | Low at high current levels |

| Voltage rating | Low to medium (< 600V) | High (>600V) |

| Current rating | Low to medium | High |

| Common applications | SMPS, Chargers, DC-DC | Motor Drives, Solar Inverters |

Click for larger version

When to Use a MOSFET

A MOSFET is often the best option when efficiency at high speed and lower voltages is the priority.

Switch-Mode Power Supplies (SMPS): Your laptop brick and phone charger use MOSFETs. High switching frequencies allow these devices to be tiny because the transformers and filters don't need to store as much energy per cycle.

DC-DC Converters: In automotive electronics or battery-managed systems where the voltage is typically 12V, 24V, or 48V, the MOSFET’s low on-resistance is unbeatable.

Class D Audio Amplifiers: The high-speed switching of MOSFETs allows for the creation of high-fidelity audio signals through Pulse Width Modulation (PWM) with minimal heat generation.

When to Use an IGBT

The IGBT excels in areas where high current and voltage, but slower switching speeds are required. It comes into its own for many industrial and high-power grid applications.

Variable Frequency Drives (VFDs) and Motor Control: Controlling a 50HP industrial motor requires handling massive current spikes and high voltages. Since motors are inductive loads and don't require MHz switching speeds (usually 8-16 kHz), the IGBT is the perfect fit.

Electric Vehicle (EV) Inverters: While Silicon Carbide (SiC) MOSFETs are making inroads, many EV traction inverters still rely on IGBTs to convert the high-voltage DC from the battery into the AC needed for the motor.

Uninterruptible Power Supplies (UPS): For large-scale data centers, the UPS must handle enormous power levels. The IGBT's ability to manage high current density makes it more cost-effective and reliable here than a massive array of paralleled MOSFETs.

Induction Heating: High-power induction cooktops and industrial smelting furnaces use IGBTs to handle the heavy resonant currents required to generate magnetic fields.

The Future: Wide Bandgap (SiC and GaN)

It is worth noting that the traditional MOSFET vs. IGBT debate is being disrupted by the growing availability and use of Silicon Carbide, SiC and Gallium Nitride, GaN.

SiC MOSFETs are essentially "supercharged" MOSFETs that can handle high voltages (up to 1700V and beyond) while maintaining incredibly fast switching speeds. They are slowly replacing IGBTs in high-end EV inverters.

GaN Transistors are taking over the low-to-medium voltage space, offering even higher speeds and smaller sizes than traditional Silicon MOSFETs.

How to Choose?

To simplify any decision-making process, its worth asking three questions to help summarise and clarify what will be best:

What is my operating voltage? If it’s under 250V, go MOSFET. If it’s over 1000V, go IGBT.

What is my switching frequency? If it’s over 50kHz, you almost certainly need a MOSFET.

What are my thermal constraints? If you are running high current in a tight space, the IGBT’s lower conduction loss at high heat might be your saviour.

Both devices are essential tools in the modern engineer's kit. By understanding the physics of the unipolar MOSFET and the bipolar IGBT, you can design systems that are faster, cooler, and more reliable.

-->  Written by Ian Poole .

Written by Ian Poole .

Experienced electronics engineer and author.

More Electronic Components:

Batteries

Capacitors

Connectors

ADC

DAC

Diodes

FET

Inductors

Memory types

Phototransistor

Quartz crystals

Relays

Resistors

RF connectors

Switches

Surface mount technology

Thyristor

Transformers

Transistor

Unijunction

Valves / Tubes

Return to Components menu . . .